WE HELP KIWI BUSINESSES SOURCE AND MANUFACTURE THEIR PRODUCTS PROFITABLY

We link you with world-best production capabilities, we cover the detail of contract manufacturing and logistics. Quality, on time, at the right price, consistently. WE MANAGE THE RISK; YOU MAKE THE GAINS, leaving you to focus on what you do best.

Kiwis deal with Kiwis – Linkeight is the conduit between Kiwi businesses and overseas factories.

CONTRACT

MANUFACTURING

INDUSTRIAL

PRODUCT SOURCING

FACTORY

CONSULTANCY &

ASSESSMENT

WE HELP KIWI BUSINESSES SOURCE AND MANUFACTURE THEIR PRODUCTS PROFITABLY

We link you with world-best production capabilities, we cover the detail of contract manufacturing and logistics. Quality, on time, at the right price, consistently. WE MANAGE THE RISK; YOU MAKE THE GAINS, leaving you to focus on what you do best.

Kiwi’s deal with Kiwi’s – Linkeight is the conduit between Kiwi businesses and overseas factories.

Our specialist procurement consultants help you source products or componentry from all over the world

Linkeight enables both large and small businesses, Kiwi entrepreneurs and manufacturers easy and transparent overseas manufacturing services focused on maximising new and existing trading opportunities.

Linkeight’s extensive networks within mainland China allow for greater flexibility and ensure tighter quality controls without restrictions such as minimum purchase quantities.

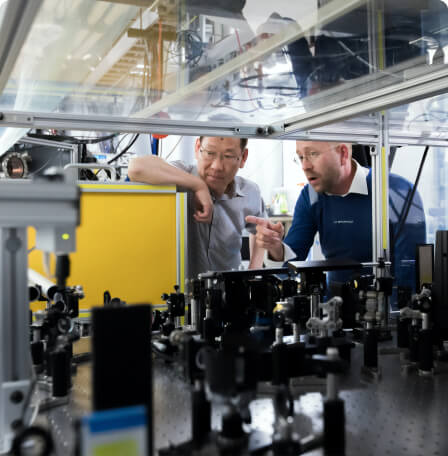

Contract Manufacturing

Let us look after some or all of your manufacturing process

We develop and manage your manufacturing process, with our integrated networks of qualified and reputable factories providing quality engineering services to deliver both components and full product assemblies.

Talk to us about:

- Casting, machined components and tooling

- Manual or CNC cutting

- Pressed and formed parts

- Heavy and light fabrication

- Prototyping and modelling CAD services

Industrial Product Sourcing

Off-the-shelf product solutions at the most profitable level.

Industrial Product Sourcing with Linkeight provides you a business and support system that manages the risk of dealing with global manufacturers. It is a method that focuses on sourcing quality products, and delivering them on time, at the right price, consistently.

Talk to us about:

- Factory fit

- Sampling

- Quality assurance

- Shipping and logistics

Factory Consultancy & Assessment

Are you looking to manufacture a product offshore?

Linkeight can take the stress out of dealing with China by qualifying a factory for the production of your product. We provide reports of our findings, including relevant photographs, videos, copies of relevant documentation and any other requested materials.

Talk to us about:

- Factory capability assessment

- Factory qualification assessment

- Production monitoring

- Company information and legal status reports

At Linkeight we work with both large and small businesses to deliver clear and easy global manufacturing solutions. Explore the customer stories below to learn more about what it’s like to work with Linkeight and the scope of projects that we can work on.

Espresso Corp

ESPRESSO CORP Long-term Linkeight partnership eliminates supply chain stress. Espresso Corp is a New Zealand based company which specialises in developing innovative products and services

Koakoa

KOAKOA Doing business right in China made easy. Chris Barber, owner of Koakoa has worked with Jeremy from Linkeight across two very different businesses. Five

Poultry Client

POULTRY CLIENT Feeding success: Linkeight’s recipe for efficiency in poultry processing plants A leading New Zealand-based poultry producer faced challenges in streamlining their manufacturing processes,

FREQUENTLY ASKED QUESTIONS

Yes we can, provide us a 3D CAD file or we can create that using our designer. We can prototype through 3D printing or CNC machining (utilising CAM software).

We specialise in plastic and metals but have also worked with glass, foams and wood.

We can accept 3D native files from most CAD software packages (preferably .stp or .IGS). 2D files (.dxf or .dwg) with pdf working files to accompany. Linkeight can provide these file types for you if required.

Quality controls are specific by customer but typically include material checks, dimensional validation, finishing validation checks (includes paint, powder coating, galvanizing). The rate of checking is typically 1-5% of production quantity, at random. Checking rates will increase to as high as 20% if any issues are found.

Yes, design can include

conceptual 3D designs, finalisation of 3D design and 2D working files.

Bulk production supply generally take 90 days as a guide after the design is finalised but is dependent on the complexity of the product.

Production lead time could be as fast as 15-20 days.

We stand by our supplier partners who are experts in their fields and most issues can be resolved fairly quickly.

Depending on the manufacturing process, costs can vary and include set up charges for moulds in addition to the price per unit. Typically our quoted price is FIS to our clients premise. As we trade in USD there may be some price fluctuation between orders from time to time.

No, this is included in our unit pricing for delivered goods.

In New Zealand dollars direct to the nominated Linkeight bank account.